Lantek Expert Punch

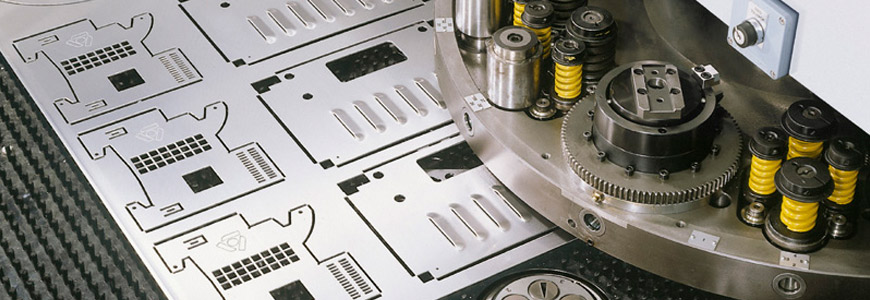

Lantek Expert Punch is a specially designed CAD/CAM nesting software designed for automating the programming of CNC punching machines. It is the result of over 30 years of Lantek experience in close collaboration with machine tool manufacturers and users.

Lantek Expert Punch offers an advanced, intuitive, and friendly interface that improves programming efficiency.

Product Specifications

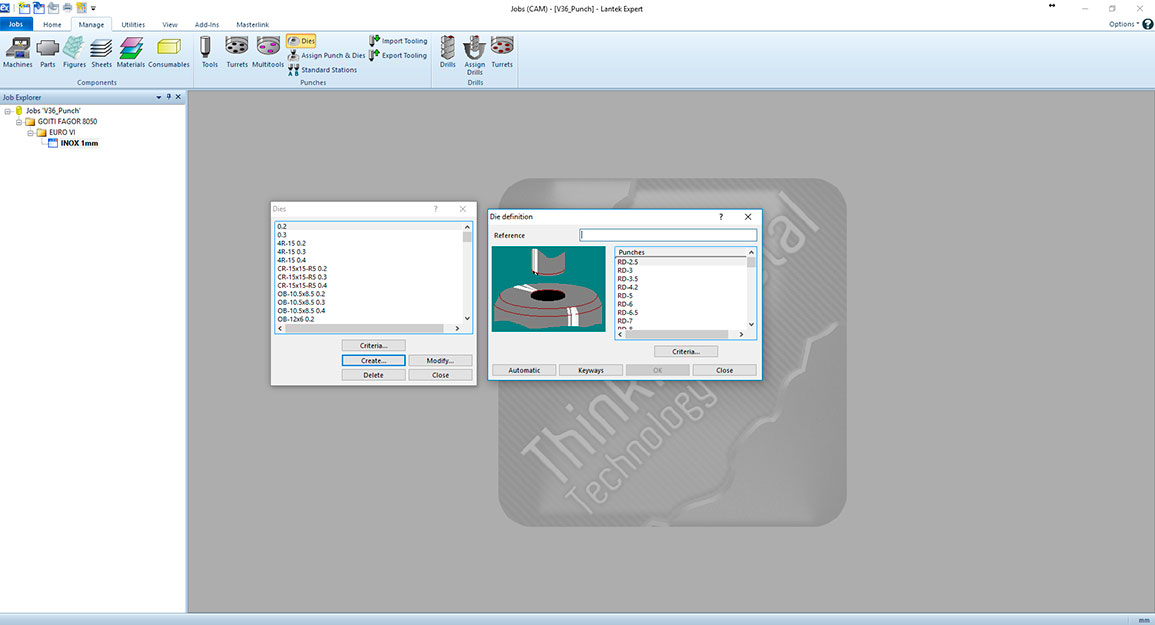

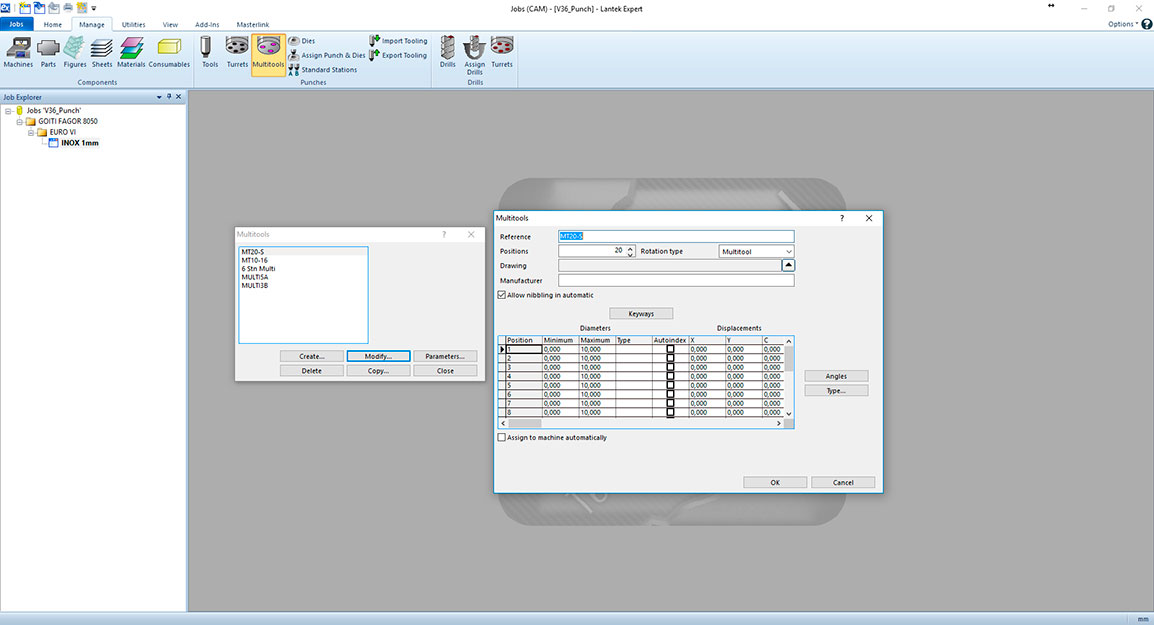

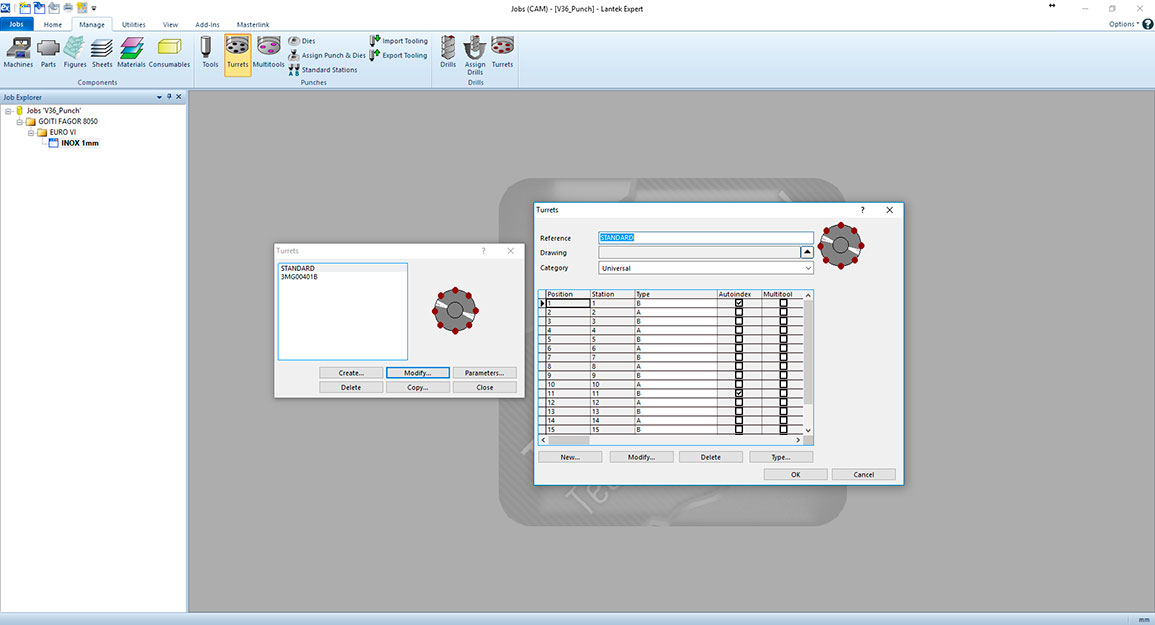

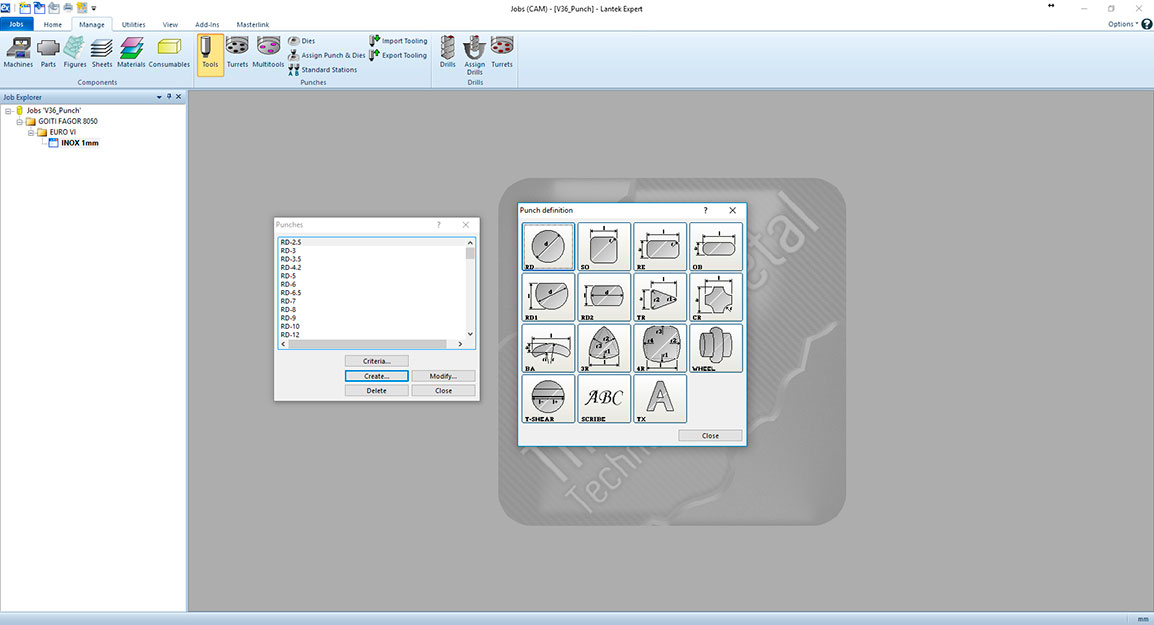

Management of Punches, Dies, Turrets…

Lantek Expert Punch manages Autoindex tools, MultiTool stations, and all tool types from the most standard tools to tools for forming, embossing, drilling, threading, stamping, rolling, and more.

The system takes into account the characteristics of each station of the turret punch and linear tool store.

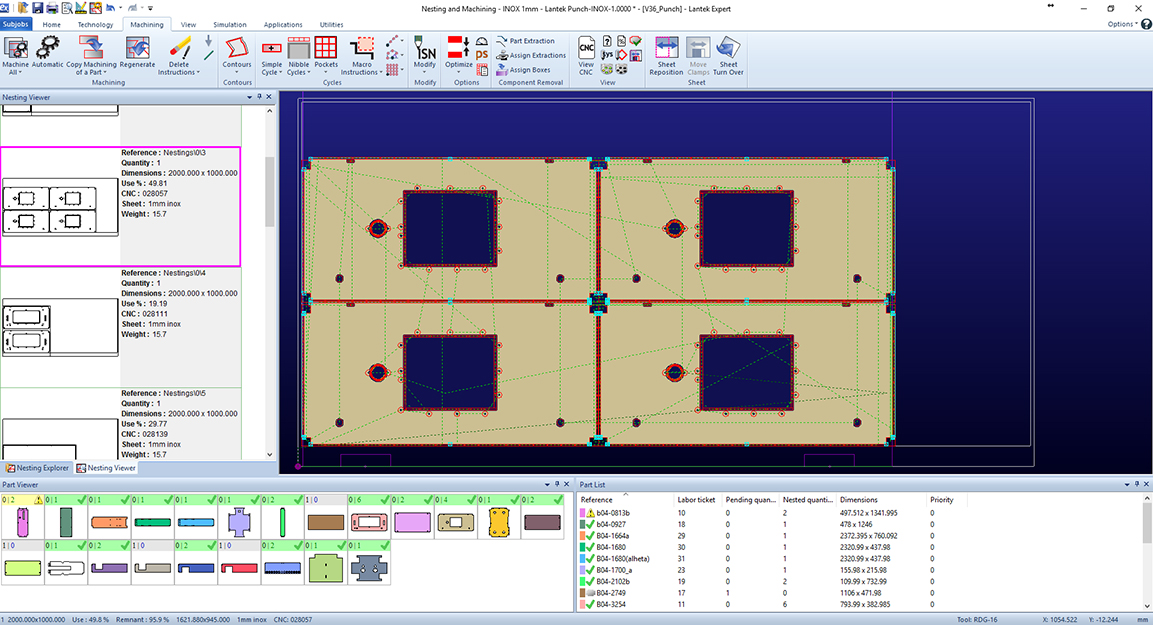

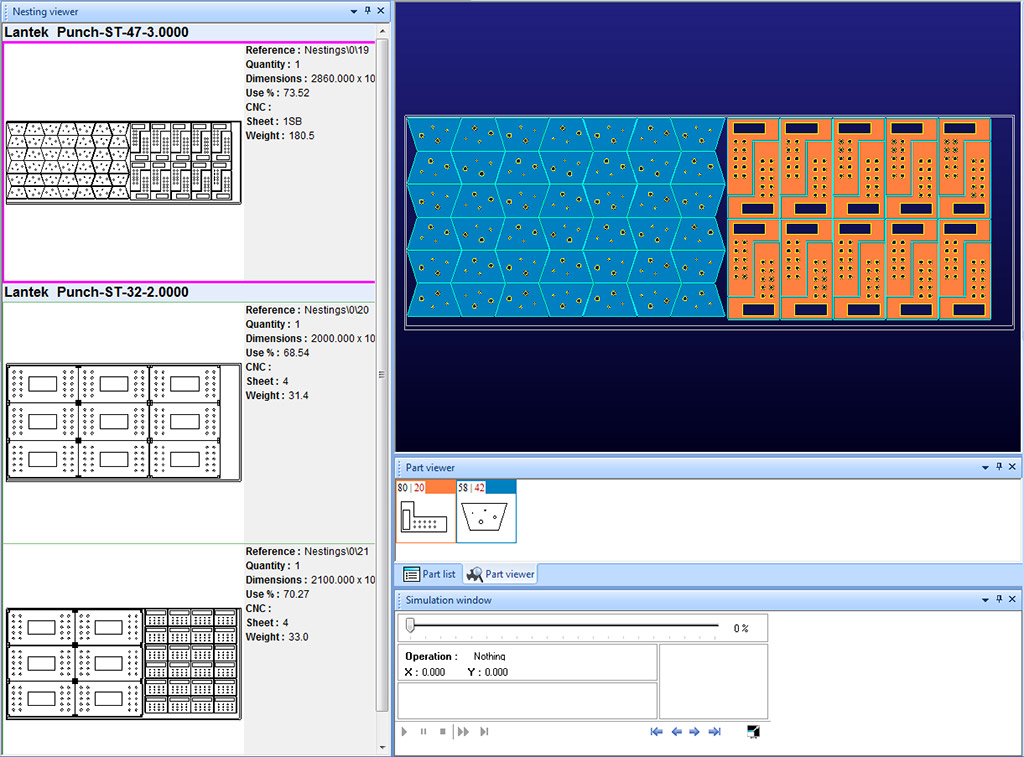

Nesting

Lantek Expert Punch offers automatic and manual nesting with great flexibility and optimum performance. The combination of automatic nesting, along with manual nesting functions such as grid copying, moving, and rotating, proves to be a very powerful tool.

Lantek Expert Punch automatic nesting optimizes part arrangement on the sheet, offering different options for common punching on regular and irregular parts.

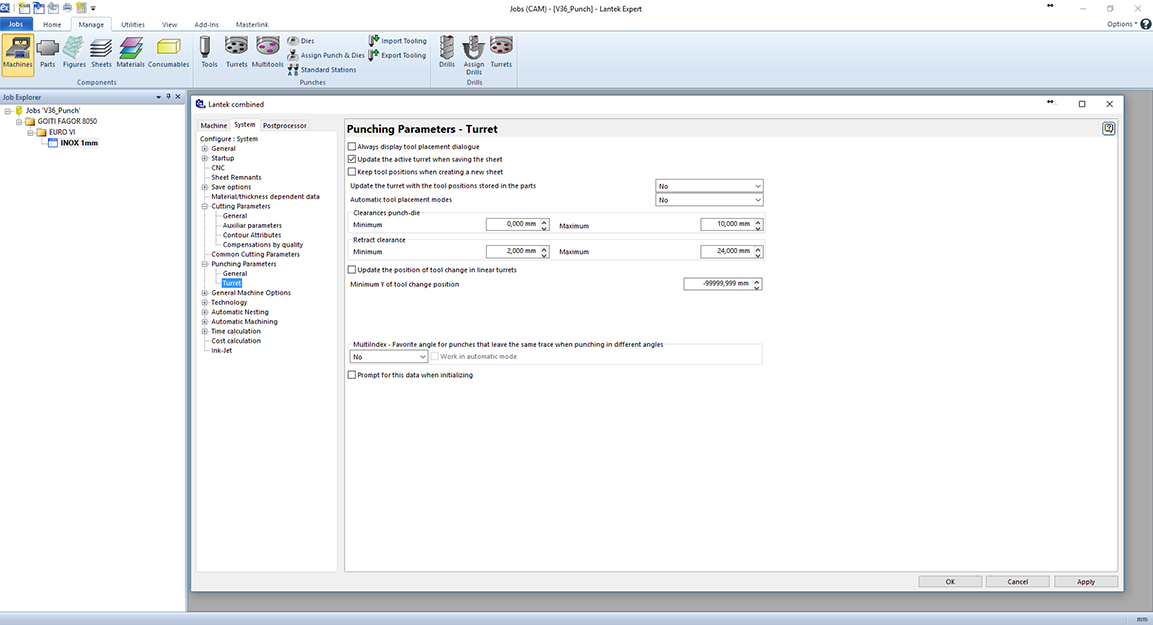

Automatic Punching

The machining of geometry in Lantek Expert Punch is totally automatic in accordance with the parameters that are configured by the user and in consideration of the machine limitations. Lantek Expert Punch has advanced options which allow full flexibility for machining, whether punching is automatic or semi-automatic.

Lantek Expert Punch stands out among competitors because of the functions it gives users for carrying out common punching on regular and irregular parts. This system manages the sheet reposition automatically, depending on different strategies chosen by the user. The system also takes various optimization criteria into account, i.e., by path and by angles. The modify option provided by Lantek allows the user to easily change machining order and sequence, micro-joints, punches, and more.

The CNC file is generated automatically and can further generate expanded and sub-program output, depending on the requirements of the machine tool. The user may personalize, in an easy way, the machining of specific parts by means of machining macros for specific geometry.

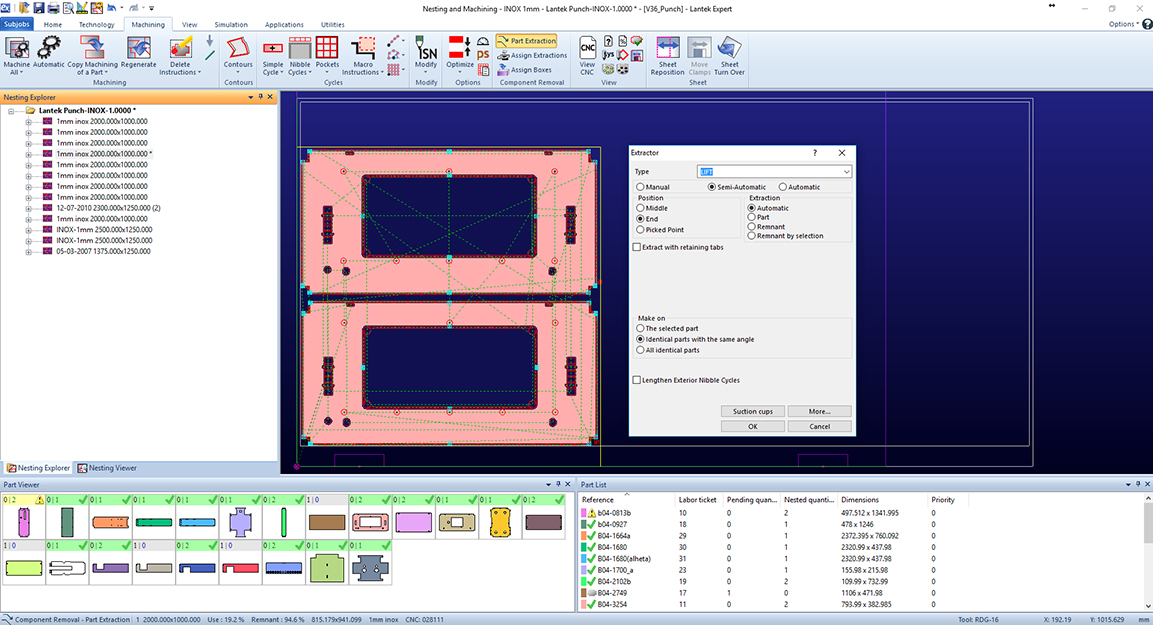

Component Removal

(Manual and Automatic)

Lantek Expert Punch controls all possible ways of removing parts from the sheet automatically. This includes: micro-joints, work chutes, machine stop, part picking systems, and integrated angle shear.

Technical Characteristics

Lantek Expert Punch options are fully integrated into one program. Lantek Expert is fully integrated with Lantek Integra, an ERP which offers different CAD/CAM/ERP solutions for the sheet metal and fabrication sector. Additionally, Lantek Expert is designed to connect to external ERP systems.

Other features of Lantek Expert Punch are:

- Teamwork – This system can work autonomously or be installed as a part of a network. By using the floating license option, multiple users can access the system.

- Parametrics Parts Library – The Lantek Expert Punch solution has a wide library of parametric parts into which the user can add their own designs.

- Open Database – This database is open and enables the user to access it to find parts, manufacturing orders, plates, etc. by using criteria such as: material, thickness, client, date, etc.

- ۲D Design – Thanks to advanced geometry options, the user can design any 2D geometry easily and quickly. Included in the CAD system are options to copy, mirror, scale, verify geometry, and fix drawing discrepancies.

- Intelligent Import/Export – Lantek Expert Punch may be linked to the major CAD systems on the market (DXF, DWG, IGES, DSTV, etc.).

- Integration – Lantek Expert works with the mainstream 3D design systems (SolidWorks®, Autodesk Inventor®, Solid Edge®, Catia®, and more.)

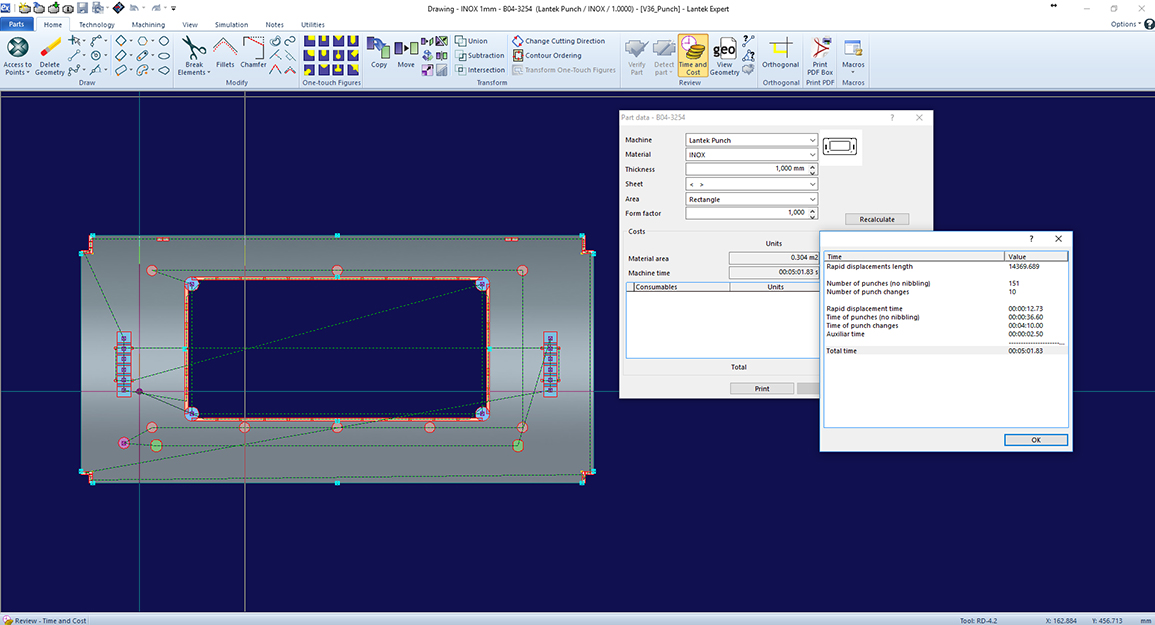

- Time and True Cost Calculations – Lantek Expert manages all the technology of the machine and calculates time and cost by piece and by sheet. With this information, the user can create quotations, check the volume of work for each machine, and print any required reports.

Added Technologies

(Shearing & Cutting)

Lantek Expert Punch supports both shearing and combination machines with a laser/plasma cutting head. Shearing and laser cutting are managed automatically and very easy to use.